- Home

- Product >

PRODUCT CATEGORY

RECOMMENDED PRODUCTS

〇 Brand laser cutting head

〇 Laser Nozzle

〇 Protective Window Lens

〇 Laser Ceramic

〇 Focus & Colliminating Lens

〇 Lens Seat & Seal Ring

〇 Capacitive Sensor

〇 FSCUT/Friendess Control Series

28mm H15 Normal Single/Double

Raytools BT240S

〇 Handheld box

- Consumables >

PRODUCT CATEGORY

RECOMMENDED PRODUCTS

〇 Cleaning Kits

〇 Disassembly tools

〇 Filter Element

〇 Dust Cover

〇 CLARIANT antifrogen N

〇 EUBO lubricating oil

〇 Fiber Lasers

〇 Optical fiber protective cap

Cleaning Kits 10 Inch PP Cotton Filter Element

〇 Laser goggles

〇 Spare Parts For YAG

- Service support >

Electrical circuit repair

Focus collimator replacement

Laser cutting head maintenance

Cavity cleaning Crystal repair

Cutting equipment Laser repair

Laser sensor handheld box repair

- Panso Infos >

Laser Encyclopedia

Job Offers

- About us

- Contact us

he fiber laser cutting machine has three major consumables, which protect the lens, nozzle, and ceramic ring.

An important part of the cutting head of the fiber laser cutting machine is a ceramic ring, which is used to transmit the electrical signals collected by the laser head nozzle and stabilize the normal operation of the fiber laser cutting machine. The equipment we often encounter suddenly stops, the laser head hits the face and other failures are actually caused by the instability of the laser ceramic ring. Therefore, it is very important to choose a high-quality ceramic ring for fiber laser cutting machine. I will introduce you how to choose a high-quality laser ceramic ring.

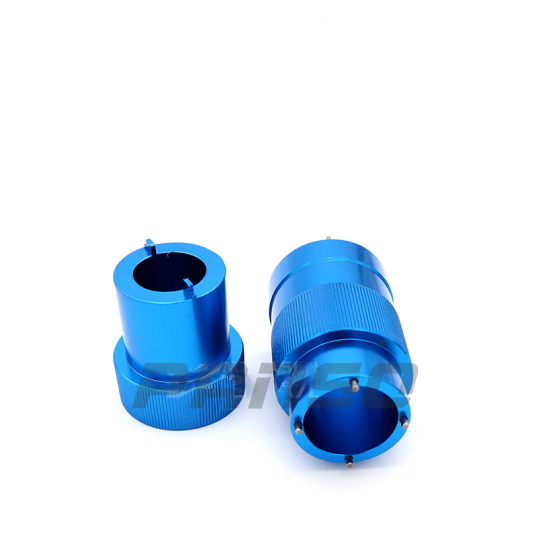

The laser ceramic ring is composed of a ceramic body, a stainless steel piece and a copper needle. The ceramic body is mainly used to maintain sufficient contact with the nozzle to transmit the electrical signal to the copper needle, and the copper needle transmits the electrical signal to the transmission line, and then the internal line of the laser head transmits the signal to the controller.

After using the old laser ceramic ring on the market for a period of time, the contact between the stainless steel part and the copper pin is poor, and the copper pin is even broken, resulting in unstable or no signal. Fiber laser cutting machines will also stop working for these reasons, or even hit the working surface, causing losses to users.

Signal stability: High-quality high-quality laser conductive silver glue ceramic ring is used to ensure a close connection with the stainless steel parts of the ceramic body, and at the same time ensure the conductivity of the copper needles and stainless steel parts.

Many laser ceramic rings on the market replace conductive silver glue with inferior glue. In a high temperature environment, the glue will dissolve and the stainless steel parts will become loose, and the conductivity of the product cannot be guaranteed. The accident of the laser head hitting the workpiece is easy to happen, causing great loss to the user.

The high-quality stainless steel parts can ensure good concentricity after being assembled with the ceramic body and undergo a comprehensive inspection. Therefore, when the nozzle is replaced, the concentricity error between the two nozzles can be reduced. If a high-quality nozzle is selected, there is no need to reset the fiber laser cutting machine when the nozzle is in contact with the nozzle. The working time loss is greatly reduced, and the working efficiency of the fiber laser cutting machine is greatly improved.

Nowadays, the price of ceramic rings on the market is chaotic, and the price of original ceramic rings is relatively high, especially the original imported ceramic rings, but some domestic ones have quite stable performance. Ming's laser ceramic ring adopts imported ceramic materials and is precision processed, which has good brittleness and temperature adaptability.

Product

Sales Manager:Roy Ren

ADD: Xingyu Science Park, No. 688, Chunshen Road, High tech Zone, Jinan City, Shandong Province CHINA

E-mail:roy370124@gmail.com

Tel:+86 150 9898 4876

whatsapp: +86 86 150 9898 4876