- Home

- Product >

PRODUCT CATEGORY

RECOMMENDED PRODUCTS

〇 Brand laser cutting head

〇 Laser Nozzle

〇 Protective Window Lens

〇 Laser Ceramic

〇 Focus & Colliminating Lens

〇 Lens Seat & Seal Ring

〇 Capacitive Sensor

〇 FSCUT/Friendess Control Series

28mm H15 Normal Single/Double

Raytools BT240S

〇 Handheld box

- Consumables >

PRODUCT CATEGORY

RECOMMENDED PRODUCTS

〇 Cleaning Kits

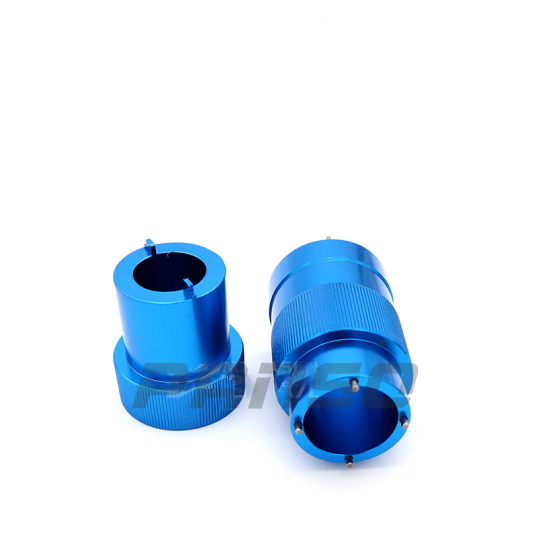

〇 Disassembly tools

〇 Filter Element

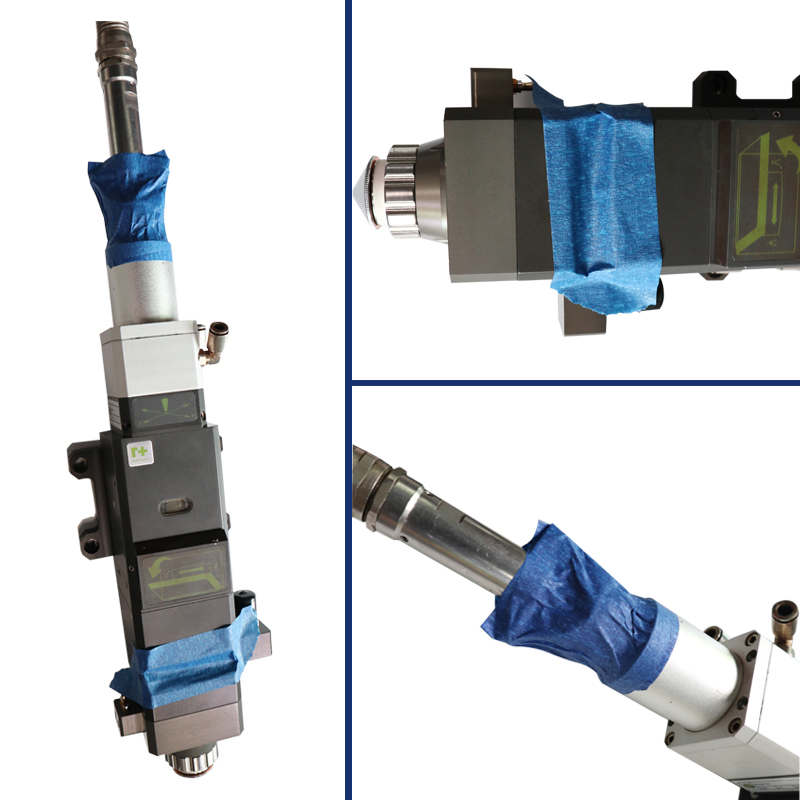

〇 Dust Cover

〇 CLARIANT antifrogen N

〇 EUBO lubricating oil

〇 Fiber Lasers

〇 Optical fiber protective cap

Cleaning Kits 10 Inch PP Cotton Filter Element

〇 Laser goggles

〇 Spare Parts For YAG

- Service support >

Electrical circuit repair

Focus collimator replacement

Laser cutting head maintenance

Cavity cleaning Crystal repair

Cutting equipment Laser repair

Laser sensor handheld box repair

- Panso Infos >

Laser Encyclopedia

Job Offers

- About us

- Contact us

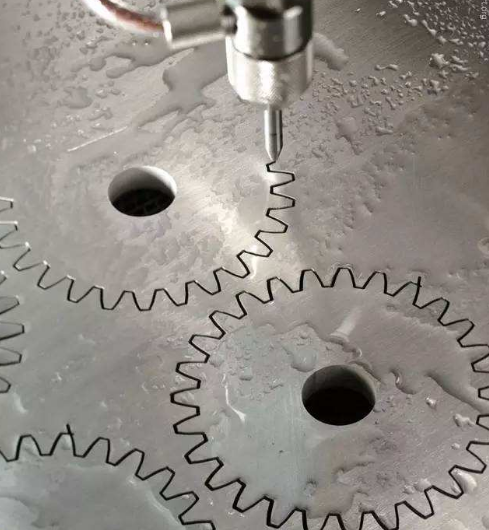

How to properly maintain the cutting head in daily work? Generally speaking, the maintenance of the cutting head includes the following:

1. Clean

Before any maintenance, it is strongly recommended to clean the cutting head first. Remove any existing dirt to prevent any contaminants from entering the cutting head cavity.

2. Check air tightness

Regularly check the leakage of the laser head. If necessary, the gaskets and gaskets (vulnerable parts) can be replaced. (Our Taobao stores are all in stock)

3. Replace vulnerable parts

If the following parts are damaged: nozzle, ceramic body, protective lens, seal ring, must be replaced. (Our Taobao stores are all in stock)

4. Electronic contacts

In order to ensure that the sensor system can work normally, the user must ensure that the electrical contacts of the following components are clean: nozzle electrode and ceramic parts; sensor and BNC interface.

5. Corrosion of water cooling circuit

Avoid corrosion of the water-cooling circuit; regularly check the microbial contamination of the cooling water (recommended once every six months). If the microbial value exceeds the standard, the water cooling circuit must be cleaned and the cooling water must be replaced.

However, the editor summarized the common problems in the maintenance process of users, and made the following warm reminders:

1. Keep the outside of the cutting head clean: to prevent accumulated contaminants, enter the cutting head cavity when replacing parts.

2. Condensation caused by excessive temperature difference: adjust the temperature of the cooling water according to the temperature change on site to prevent condensation.

3. Do not continue to use the protective lens when there are burning spots: the protective lens with burning spots will affect the normal operation of the optical lens and cause greater losses

4. Ensure the cleanliness of the cutting gas: Before use, it is necessary to check whether the gas and pipeline have residues, water vapor, oil and other pollutants. So as not to protect the lens from contamination.

5. When the sealing ring is defective, it needs to be replaced in time: a damaged sealing ring will cause the sealing function to decline and increase the risk of internal contamination of the cutting head.

6. Do not use the lower protective lens on both sides: to avoid damage to the protective lens of the focusing lens.

7. Do not use sealant or raw tape to connect the air path of the cutting head: lest pollutants enter the air path and block the air path, causing the cutting head to fail to operate normally.

Product

Sales Manager:Roy Ren

ADD: Xingyu Science Park, No. 688, Chunshen Road, High tech Zone, Jinan City, Shandong Province CHINA

E-mail:roy370124@gmail.com

Tel:+86 150 9898 4876

whatsapp: +86 86 150 9898 4876