- Home

- Product >

PRODUCT CATEGORY

RECOMMENDED PRODUCTS

〇 Brand laser cutting head

〇 Laser Nozzle

〇 Protective Window Lens

〇 Laser Ceramic

〇 Focus & Colliminating Lens

〇 Lens Seat & Seal Ring

〇 Capacitive Sensor

〇 FSCUT/Friendess Control Series

28mm H15 Normal Single/Double

Raytools BT240S

〇 Handheld box

- Consumables >

PRODUCT CATEGORY

RECOMMENDED PRODUCTS

〇 Cleaning Kits

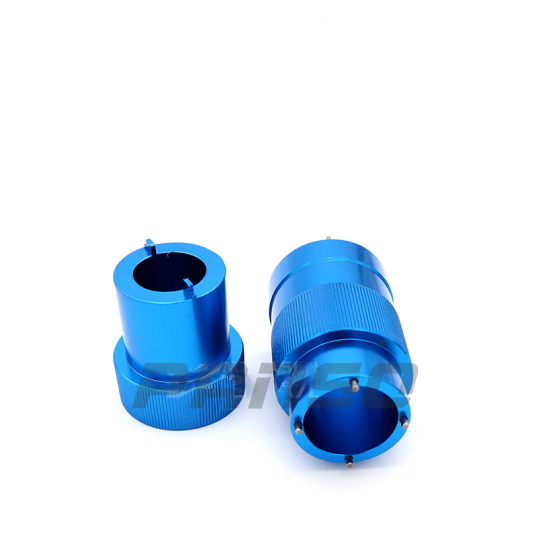

〇 Disassembly tools

〇 Filter Element

〇 Dust Cover

〇 CLARIANT antifrogen N

〇 EUBO lubricating oil

〇 Fiber Lasers

〇 Optical fiber protective cap

Cleaning Kits 10 Inch PP Cotton Filter Element

〇 Laser goggles

〇 Spare Parts For YAG

- Service support >

Electrical circuit repair

Focus collimator replacement

Laser cutting head maintenance

Cavity cleaning Crystal repair

Cutting equipment Laser repair

Laser sensor handheld box repair

- Panso Infos >

Laser Encyclopedia

Job Offers

- About us

- Contact us

With the rapid development of society and economy, fiber laser cutting machines have been widely used due to their advantages of low energy consumption, no pollution, and simple operation. However, due to some improper operation factors, the nozzle of the laser head will be blocked or damaged, which will reduce the cutting accuracy of the nozzle of the laser head and affect the service life of the cutter. Now I have analyzed the main reasons for the failure of the laser nozzle.

First of all, we know that laser nozzles are usually divided into single layer and double layer, the nozzle diameter ranges from 1.0mm to 3.0mm, and there are 5 inverted tapered holes. These characteristics are not tight to ensure that the nozzles dissipate heat, but they are not easy to contact the slag. However, due to the defects of the nozzle itself and the performance of the cutting machine, it will cause nozzle loss.

Two reasons for the failure of the laser nozzle

1. Nozzle "dust accumulation" causes the hole diameter to become larger

Because the soft material of a single laser nozzle is easily deformed and rubbed. During the operation of the machine, the nozzle will directly contact the slag. If the melting point is enclosed in the orifice, the sheet material that is easy to think of "dust accumulation" will be cut, which will cause the beam energy of the deviation direction of the laser to weaken, resulting in a decrease in cutting accuracy. Affect the quality of cutting. When dust is accumulated to a certain extent, it will be washed away at high temperature and high pressure gas flow, resulting in a large diameter.

2. Nozzle deformation and slag particles

In the cutting process, it is divided into two situations: When the laser cutting head is in the vertical direction, the collision sensor causes the mechanical protection of the machine to be stopped. Then, the impact in the horizontal direction would naturally be caused by the tilted collision cutting material laser cutting head. When the laser cutting head is heavy, the sensing can immediately stop the protection although mechanical operation, but at the same time, this force is due to the laser head, the laser head is tilted, the deviation of the laser beam, and the nozzle material is in direct contact, resulting in The deformation of the nozzle can not continue cutting; when the laser head, the sensor can not be shut off the mechanical protection mechanism in time, causing the slag to enter the nozzle contact light, and the high pressure air blown into the molten slag will cause the loss in the laser head.

The damage of the nozzle not only affects the life of the laser head cutting machine, but also affects the work process and the perfection of the product. Therefore, the mechanical parts and components should be inspected, cleaned and maintained in time after the machine is used, so as to ensure the use time of the parts .

Product

Sales Manager:Roy Ren

ADD: Xingyu Science Park, No. 688, Chunshen Road, High tech Zone, Jinan City, Shandong Province CHINA

E-mail:roy370124@gmail.com

Tel:+86 150 9898 4876

whatsapp: +86 86 150 9898 4876